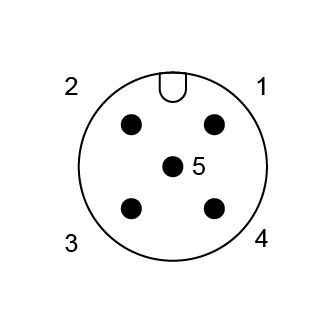

Core Count : 4P

Category : Female

Direction :90°

Applications : Power, Signal

90-degree all-metal assembled bent-type screw:

Precise fit of the bending angle: The 90-degree bend head is specially designed for narrow spaces such as the corners of equipment and the periphery of densely packed PCB boards. Before selecting the model, it is necessary to measure the lateral and longitudinal gaps of the installation area to ensure that the inner side of the bending angle has a ≥ 4mm operation space reserved with the equipment shell, and there is no interference from pipelines or components on the outer side. Key points for installing the bend connector: During installation, ensure that the bending angle direction is completely consistent with the direction of the cable, and avoid forcibly bending the cable (bending radius ≥ 6 times the cable diameter); After tightening the screws, gently pull the cable to check, ensure that the connector has no force deviation, and if necessary, use cable ties to fix the cable to share the pulling force. It is widely used in industrial robot joints, automated production line equipment, new energy energy storage cabinets, outdoor environmental monitoring instruments, and dense PCB board interconnections, etc., and is suitable for complex industrial environments with frequent vibrations and restricted wiring.

|

Product model

|

Core

|

Rated current

|

Rated voltage

|

Wire gauge / Dimension

|

||

|

A/C

|

D/C

|

AWG

|

mm²

|

|||

| MC12DF-04N4LJZSR601 |

4

|

4A

|

250V

|

250V

|

22

|

0.34

|

| Core | 2A | 3A | 4A | 5A |

| male end |

|

|

|

|

| 6A | 8A | 12A | 17A | |

|

|

|

|

|

|

| 4B | 5B | 3C | 4C | |

|

|

|

|

|

|

| 5C | 6C | 4D | ||

|

|

|

|

||

| Core | 2A | 3A | 4A | 5A |

| female connector |

|

|

|

|

| 6A | 8A | 12A | 17A | |

|

|

|

|

|

|

| 4B | 5B | 3C | 4C | |

|

|

|

|

|

|

| 5C | 6C | 4D | ||

|

|

|

|

|

The connector must not be plugged or unplugged under load. Failure to follow the instructions and improper use can result in personal injury.

The development of the connector is aimed at being applied in factory engineering, control and electrical equipment construction. Users are responsible for checking whether the connector can also be used in other applications.

Connectors used in circuits with dangerous voltages that cause electric shock must be installed and used only by personnel who have received training in electrical engineering, or under their supervision, while taking into account the applicable regulations and standards.

Users must take appropriate security measures to ensure that the connectors do not accidentally disconnect.

When installing, apply moderate force and use the special tool to tighten the nuts. Avoid excessive force to prevent the shell from deforming or the pins from bending. Ensure that the plug and socket are fully engaged. Do not power on the device when not locked in place to prevent arc discharge due to poor contact.

The plug connectors with an enclosure protection rating of IP67 and IP68 are not suitable for use in water. When used outdoors, the plug connectors must be protected against corrosion separately. For further information on IP protection ratings, please refer to "Technical Information".